|

|

| Brand Name: | RENOXBELL |

| Model Number: | AL-1100A |

| MOQ: | 500㎡ |

| Price: | USD25-USD50/㎡ |

| Packaging Details: | plastic masking film and bubble sheets |

| Payment Terms: | T/T or L/C |

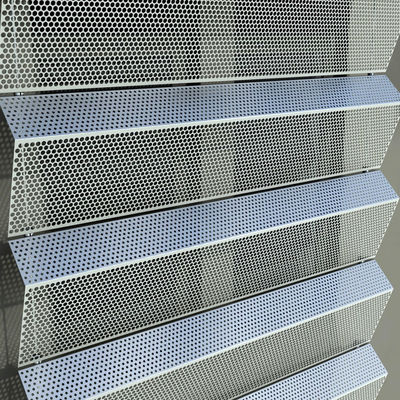

Perforated Corrugated Aluminum Sheet Plate Panel Customized For Rainscreen Wall Decoration

Aluminum Sheets is a versatile and durable product that is widely used in the construction industry. With a thickness range of 0.5-6.0mm and various surface treatments, it can meet the needs of different projects and add a touch of modern aesthetic to any building.

The thickness of Aluminum Sheets ranges from 0.5mm to 6.0mm, making it suitable for a wide range of applications. Whether it is used for ceiling decoration or exterior cladding, this product can provide the desired level of strength and durability.

Aluminum Sheets can be treated with different surface finishes to achieve the desired appearance and functionality. The options include Chromaking, Powder Coating, PVDF Coating, and Anodizing. These surface treatments not only enhance the visual appeal of the product but also improve its resistance to corrosion, weathering, and scratches.

Our Aluminum Sheets are manufactured using advanced CNC machines and robots, ensuring high precision and consistency in every piece. This technology also allows for customization, making it possible to produce sheets in various sizes and shapes to meet the specific needs of each project.

Our Aluminum Sheets are made from high-quality aluminum alloy or other metals, making them strong and durable. This material is also lightweight, making it easy to handle and install, reducing the overall weight of the building, and providing cost savings.

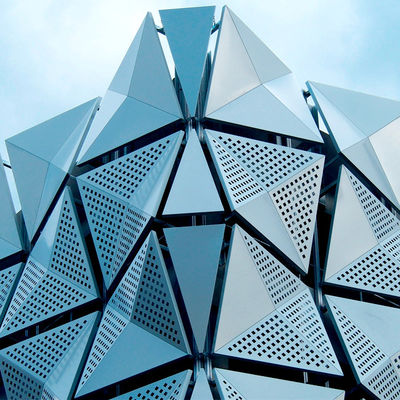

Aluminum Sheets are suitable for a wide range of applications in different types of buildings, including residential, commercial, government, and civil buildings. They can be used for interior and exterior decoration, such as ceilings, walls, facades, and more.

Our Aluminum Sheets are made from 100% recyclable material, making them a sustainable choice for building projects. This also contributes to a healthier environment.

We are confident in the quality of our product, and therefore, we offer a 5-year warranty to ensure customer satisfaction and peace of mind.

Aluminum Sheets have a long service life, with a lifespan of more than 20 years. This makes them a cost-effective choice in the long run, as they require minimal maintenance and replacement.

Our Aluminum Sheets are resistant to corrosion, weathering, and impact, making them suitable for use in various environments and climates.

The lightweight nature of Aluminum Sheets makes them easy to handle and install, reducing labor and transportation costs.

With its lightweight and customizable nature, our Aluminum Sheets are easy to install, saving time and effort on construction projects.

From glossy to matte, smooth to textured, our Aluminum Sheets come in a variety of surface finishes, allowing for endless design possibilities.

We understand that every project is unique, and that's why we offer customization options for our Aluminum Sheets. This allows for the creation of tailored solutions for each project.

Our advanced technology ensures high precision in the production of Aluminum Sheets, providing a perfect fit and finish for every piece.

With its long service life, low maintenance, and installation costs, Aluminum Sheets are a cost-effective choice for any building project.

In conclusion, Aluminum Sheets are a highly versatile and durable product that can add both functionality and aesthetic value to any building. With its various surface finishes, customizable options, and advanced technology, it is the perfect choice for ceiling decoration and exterior cladding. Moreover, our commitment to using environment-friendly materials and providing a 5-year warranty further ensures the quality and reliability of our product. Choose Aluminum Sheets for your next building project and experience its many benefits for yourself.

![]()

Aluminum sheets, produced by RENOXBELL, are a highly versatile building material suitable for a wide range of applications in various industries. With its superior quality and advanced technology, AL-1100A has become a popular choice for residential, commercial, government, and civil buildings in China and around the world.

RENOXBELL's Aluminum Sheets are made from environmentally friendly materials, making them a sustainable choice for construction projects. The aluminum used is 100% recyclable, reducing the impact on the environment and promoting a greener future.

One of the main advantages of using Aluminum Sheets is its ease of installation. The sheets are lightweight, making them easy to handle and transport, and can be fixed by self-tapping bolts, saving time and labor costs. Additionally, Aluminum Sheets require minimal maintenance, reducing long-term costs for building owners.

Aluminum Sheets are suitable for a variety of applications, including residential, commercial, government, and civil buildings. They can be used for exterior cladding, roofing, and interior decoration, providing a modern and sleek look to any building.

RENOXBELL's Aluminum Sheets are fabricated according to provided drawings and specifications, ensuring a perfect fit for each project. This allows for a seamless integration of the sheets into the building's design, enhancing its overall aesthetic appeal.

Our Aluminum Sheets are produced using CNC machines and robots, ensuring precision and consistency in the manufacturing process. The sheets undergo various processes such as cutting, punching, bending, welding, grinding, assembling, chromaking, and spray coating or anodizing, resulting in a high-quality, durable product.

RENOXBELL's Aluminum Sheets have a range of features that make them a top choice for building materials. They are lightweight, making them easy to handle and transport, while also having high impact strength, making them resistant to damage. The sheets are weatherproof, with excellent chemical resistance, ensuring their longevity in various environments. They are also available in a wide range of colors and patterns, providing endless design possibilities for building facades.

Thanks to their durability and resistance to corrosion, RENOXBELL's Aluminum Sheets have a long lifespan, making them a cost-effective choice for building owners. They can withstand harsh weather conditions, reducing the need for frequent replacements and repairs.

|

| Brand Name: | RENOXBELL |

| Model Number: | AL-1100A |

| MOQ: | 500㎡ |

| Price: | USD25-USD50/㎡ |

| Packaging Details: | plastic masking film and bubble sheets |

| Payment Terms: | T/T or L/C |

Perforated Corrugated Aluminum Sheet Plate Panel Customized For Rainscreen Wall Decoration

Aluminum Sheets is a versatile and durable product that is widely used in the construction industry. With a thickness range of 0.5-6.0mm and various surface treatments, it can meet the needs of different projects and add a touch of modern aesthetic to any building.

The thickness of Aluminum Sheets ranges from 0.5mm to 6.0mm, making it suitable for a wide range of applications. Whether it is used for ceiling decoration or exterior cladding, this product can provide the desired level of strength and durability.

Aluminum Sheets can be treated with different surface finishes to achieve the desired appearance and functionality. The options include Chromaking, Powder Coating, PVDF Coating, and Anodizing. These surface treatments not only enhance the visual appeal of the product but also improve its resistance to corrosion, weathering, and scratches.

Our Aluminum Sheets are manufactured using advanced CNC machines and robots, ensuring high precision and consistency in every piece. This technology also allows for customization, making it possible to produce sheets in various sizes and shapes to meet the specific needs of each project.

Our Aluminum Sheets are made from high-quality aluminum alloy or other metals, making them strong and durable. This material is also lightweight, making it easy to handle and install, reducing the overall weight of the building, and providing cost savings.

Aluminum Sheets are suitable for a wide range of applications in different types of buildings, including residential, commercial, government, and civil buildings. They can be used for interior and exterior decoration, such as ceilings, walls, facades, and more.

Our Aluminum Sheets are made from 100% recyclable material, making them a sustainable choice for building projects. This also contributes to a healthier environment.

We are confident in the quality of our product, and therefore, we offer a 5-year warranty to ensure customer satisfaction and peace of mind.

Aluminum Sheets have a long service life, with a lifespan of more than 20 years. This makes them a cost-effective choice in the long run, as they require minimal maintenance and replacement.

Our Aluminum Sheets are resistant to corrosion, weathering, and impact, making them suitable for use in various environments and climates.

The lightweight nature of Aluminum Sheets makes them easy to handle and install, reducing labor and transportation costs.

With its lightweight and customizable nature, our Aluminum Sheets are easy to install, saving time and effort on construction projects.

From glossy to matte, smooth to textured, our Aluminum Sheets come in a variety of surface finishes, allowing for endless design possibilities.

We understand that every project is unique, and that's why we offer customization options for our Aluminum Sheets. This allows for the creation of tailored solutions for each project.

Our advanced technology ensures high precision in the production of Aluminum Sheets, providing a perfect fit and finish for every piece.

With its long service life, low maintenance, and installation costs, Aluminum Sheets are a cost-effective choice for any building project.

In conclusion, Aluminum Sheets are a highly versatile and durable product that can add both functionality and aesthetic value to any building. With its various surface finishes, customizable options, and advanced technology, it is the perfect choice for ceiling decoration and exterior cladding. Moreover, our commitment to using environment-friendly materials and providing a 5-year warranty further ensures the quality and reliability of our product. Choose Aluminum Sheets for your next building project and experience its many benefits for yourself.

![]()

Aluminum sheets, produced by RENOXBELL, are a highly versatile building material suitable for a wide range of applications in various industries. With its superior quality and advanced technology, AL-1100A has become a popular choice for residential, commercial, government, and civil buildings in China and around the world.

RENOXBELL's Aluminum Sheets are made from environmentally friendly materials, making them a sustainable choice for construction projects. The aluminum used is 100% recyclable, reducing the impact on the environment and promoting a greener future.

One of the main advantages of using Aluminum Sheets is its ease of installation. The sheets are lightweight, making them easy to handle and transport, and can be fixed by self-tapping bolts, saving time and labor costs. Additionally, Aluminum Sheets require minimal maintenance, reducing long-term costs for building owners.

Aluminum Sheets are suitable for a variety of applications, including residential, commercial, government, and civil buildings. They can be used for exterior cladding, roofing, and interior decoration, providing a modern and sleek look to any building.

RENOXBELL's Aluminum Sheets are fabricated according to provided drawings and specifications, ensuring a perfect fit for each project. This allows for a seamless integration of the sheets into the building's design, enhancing its overall aesthetic appeal.

Our Aluminum Sheets are produced using CNC machines and robots, ensuring precision and consistency in the manufacturing process. The sheets undergo various processes such as cutting, punching, bending, welding, grinding, assembling, chromaking, and spray coating or anodizing, resulting in a high-quality, durable product.

RENOXBELL's Aluminum Sheets have a range of features that make them a top choice for building materials. They are lightweight, making them easy to handle and transport, while also having high impact strength, making them resistant to damage. The sheets are weatherproof, with excellent chemical resistance, ensuring their longevity in various environments. They are also available in a wide range of colors and patterns, providing endless design possibilities for building facades.

Thanks to their durability and resistance to corrosion, RENOXBELL's Aluminum Sheets have a long lifespan, making them a cost-effective choice for building owners. They can withstand harsh weather conditions, reducing the need for frequent replacements and repairs.