|

|

| Brand Name: | RENOXBELL |

| Model Number: | CA-001 |

| MOQ: | 500 ㎡ |

| Price: | USD25-50 per square |

| Packaging Details: | plastic masking film and bubble sheets |

| Payment Terms: | T/T, L/C |

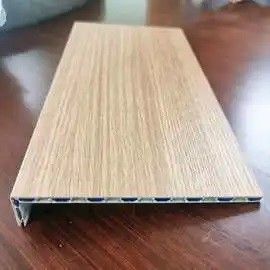

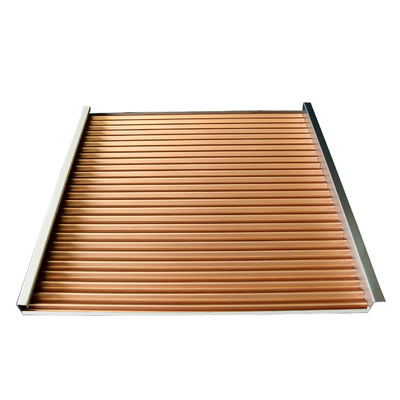

Corrugated Aluminum Composite Panel Customized For Partiton Or Wall Cladding Or Suspension Ceiling

Key Words

Aluminum alloy, aluminum plate, aluminum sheet, perforated aluminum sheet or panel, corrugated aluminum sheet or panel, perforated aluminum ceiling panel, wall panel, metal wall panel, aluminum wall panel, wall cladding panel, metal wall cladding panel, aluminum wall cladding panel, curtain wall panel, aluminum curtain wall cladding panel, building material, suspension ceiling, decoration material, construction material

We're producing 3 types of corrugated aluminum sheets or panels, first type is singe corrugated aluminum sheet with typical thickness 0.4mm to 3.0mm, the second type is 2-layer corrugated aluminum composite panel which is made from a 0.6mm to 2.0mm flat aluminum sheet and a 0.2mm, 0.25mm, 0.3mm, 0.4mm or 0.5mm corrgated aluminum sheet (corrugation height is 3mm to 20mm) by adhesive bonding, the typical total thickness of composite panels is 4mm to 22mm, it's very popular for hook-up suspension ceiling system, the third type is 3-layer corrugated aluminum panel which is made from 2 flat aluminum sheets (thickness from 0.5mm to 2.0mm) and a corrugated aluminum sheet (thickness from 0.2mm to 0.5mm and corrugation height from 3mm to 20mm or custom specifications) by adhesive bonding in sandwich way, this type of corrugated aluminum sandwich composite panels is usually used for wall cladding and decoration or partitions because of its features of great flatness, high impact strength, low weight and uniform color. All the corrugated aluminum sheets or panels are pre-coated by roller coating with PVDF or Polyester coating, it can also be made by spray coating if necessary. We can customize and fabricate the corrugated aluminum sheets or panels according to your designs, specifications and requirements.

![]()

Our Corrugated Aluminum Panels present a premium solution for various construction, architectural, and industrial applications. These panels are meticulously crafted with a focus on durability, safety, and environmental responsibility. The product is designed to exhibit a high degree of fire resistance, proudly classified under the Class A2 category, ensuring peace of mind for our customers concerning fire safety and compliance with stringent building codes.

One of the key advantages of these corrugated panels is their low weight. This attribute makes them easy to handle and install, reducing overall labor costs and structural load. Despite their lightness, these panels do not compromise on strength. High strength is a core characteristic of our product, attributed to the superior quality of aluminum used and the precise manufacturing processes that enhance their rigidity and longevity. Good flatness is another feature, ensuring that each panel presents a smooth and uniform appearance when applied to any surface.

The panels come in a variety of thicknesses ranging from 0.1mm to 2.0mm, catering to a broad spectrum of requirements and ensuring versatility across different projects. Whether you need lightweight panels for decorative purposes or thicker, more robust panels for structural applications, our product line accommodates your needs with precision.

To meet diverse customer preferences and design specifications, our Corrugated Aluminum Panels come with a roller coating color finish. This finish not only adds to the aesthetic appeal of the panels but also provides an additional layer of protection against environmental elements. The roller coating process ensures a consistent and high-quality finish that enhances the product's durability and maintains its appearance over time.

The temper of the aluminum used in our panels ranges from O-H112. This indicates that our panels are available in various states of hardness and strength, from annealed (O) to full hard (H112), providing options that accommodate different levels of malleability and formability required by our clients’ specific applications.

We take pride in our commitment to environmental sustainability. Our Corrugated Aluminum Panels are not only environmentally friendly due to their recyclability, but they also contribute to greener building practices. The aluminum's recyclable nature means that it can be repurposed at the end of its life cycle, reducing waste and conserving resources. This feature is particularly important for organizations looking to meet eco-friendly standards and for individuals who prioritize environmental consciousness in their building materials.

In terms of specifications, our corrugated aluminum panels are available in a single aluminum thickness range from 0.15mm to 3.0mm, broadening the scope of applications and providing a tailored solution for specific structural requirements. The roller coating color finish, applied with precision and care, ensures that our panels are not only robust but also visually appealing, with a range of colors to match any design palette.

In summary, our Corrugated Aluminum Panels embody the perfect blend of functionality, safety, and eco-friendliness. With attributes like fire resistance (Class A2), low weight, high strength, good flatness, and a roller coating color finish, these panels are ideal for a multitude of projects that demand quality and durability. The range of thicknesses, from 0.1-2.0mm, and the option for single aluminum thicknesses from 0.15mm to 3.0mm, coupled with the varying temper states, make our product adaptable to your unique needs. Choose our Corrugated Aluminum Panels for a sustainable, strong, and visually compelling addition to your next project.

The RENOXBELL Corrugated Aluminum Panels, model CA-001, are a versatile and innovative solution for a wide range of architectural and design applications. These panels, originating from China and boasting an ISO9001 certification, are renowned for their quality and durability. They are available with a minimum order quantity of 500 square meters and are priced competitively between USD25-50 per square meter.

RENOXBELL's Corrugated Aluminum Panels come in various grades ranging from 1000 to 7000, with alloy codes including A1100, A3003, A5052, among others, catering to diverse project requirements. The panels are of the flat panel type, and one of the key attributes is that the corrugations can be customized to requests, ensuring that each project can have a unique aesthetic or functional feature.

Color customization is another significant advantage of these aluminum panels. Clients can choose the color to match their specific design palette, ensuring that the color can be customized to complement existing structures or to create new, visually striking environments. This feature is particularly beneficial for corporate branding or when adhering to local building codes and design guidelines.

When it comes to environmental responsibility, RENOXBELL has ensured that their Corrugated Aluminum Panels are recyclable, reflecting a commitment to sustainability and eco-friendly construction practices. This aspect is increasingly important in today's construction industry, where environmental impact is a critical consideration.

The ease and speed of installation are also key benefits. The panels are designed for quick assembly, reducing labor costs and speeding up the construction process, which is a crucial factor in meeting project deadlines and budget constraints. The panels come carefully packaged in plastic masking film and bubble sheets to ensure they arrive on-site in pristine condition.

RENOXBELL's supply ability stands at an impressive 20,000 square meters monthly, ensuring that even the most extensive projects can be supplied without delay. With a delivery time of 20-30 days and flexible payment terms, including T/T and L/C, RENOXBELL accommodates various client needs and project timelines.

In summary, the RENOXBELL Corrugated Aluminum Panels are an excellent choice for a myriad of applications, from commercial facades to decorative interior features. The combination of customized corrugations, color options, environmental friendliness, and easy installation makes these panels a go-to product for architects and builders seeking quality, customizability, and sustainability.

Brand Name: RENOXBELL

Model Number: CA-001

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 500 ㎡

Price: USD25-50 per square meter

Packaging Details: plastic masking film and bubble sheets

Delivery Time: 20-30 days

Payment Terms: T/T, L/C

Supply Ability: 20,000 square meters monthly

Processing Service: Welding, Punching, Cutting, Bending

Durability: Long-lasting

Temper: O-H112

Grade: 1000-7000 series

Alloy code: A1100, A3003, A5052 Etc.

Our Corrugated Aluminum Panels feature a roller coating color finish, ensuring a vibrant and durable surface. For installation convenience, they can also be made with angle taps for fixing. With their light weight and good flatness, these panels offer easy handling and installation. Additionally, they boast high impact strength for increased longevity.

Our Corrugated Aluminum Panels come with comprehensive technical support and services to ensure your complete satisfaction with our product. Our dedicated team of experts is available to provide guidance on installation, maintenance, and best practices to maximize the lifespan and performance of your panels. We offer detailed product documentation, including technical specifications, installation manuals, and care instructions, to support your needs. Additionally, we provide troubleshooting assistance and advice for common issues that may arise during the use of our panels. Our support services are designed to provide you with the confidence and knowledge you need to effectively utilize our Corrugated Aluminum Panels for your projects.

Q: What is the brand name of the Corrugated Aluminum Panels?

A: The brand name of the Corrugated Aluminum Panels is RENOXBELL.

Q: Can you provide the model number for the Corrugated Aluminum Panels?

A: Yes, the model number for our Corrugated Aluminum Panels is CA-001.

Q: Where are the RENOXBELL Corrugated Aluminum Panels manufactured?

A: The RENOXBELL Corrugated Aluminum Panels are manufactured in China.

Q: What certifications do the RENOXBELL Corrugated Aluminum Panels have?

A: Our Corrugated Aluminum Panels are certified with ISO9001.

Q: What is the minimum order quantity for the Corrugated Aluminum Panels?

A: The minimum order quantity for our Corrugated Aluminum Panels is 500 square meters.

Q: How much do the Corrugated Aluminum Panels cost per square meter?

A: The price for our Corrugated Aluminum Panels ranges from USD25 to USD50 per square meter.

Q: How are the Corrugated Aluminum Panels packaged?

A: The panels are packaged with plastic masking film and bubble sheets to ensure protection during transportation.

Q: What is the delivery time for an order of Corrugated Aluminum Panels?

A: The delivery time for our Corrugated Aluminum Panels is typically between 20-30 days.

Q: What are the terms of payment accepted for purchasing Corrugated Aluminum Panels?

A: We accept payment through T/T (Telegraphic Transfer) and L/C (Letter of Credit).

Q: What is the supply ability of RENOXBELL for Corrugated Aluminum Panels?

A: RENOXBELL can supply up to 20,000 square meters of Corrugated Aluminum Panels monthly.

|

| Brand Name: | RENOXBELL |

| Model Number: | CA-001 |

| MOQ: | 500 ㎡ |

| Price: | USD25-50 per square |

| Packaging Details: | plastic masking film and bubble sheets |

| Payment Terms: | T/T, L/C |

Corrugated Aluminum Composite Panel Customized For Partiton Or Wall Cladding Or Suspension Ceiling

Key Words

Aluminum alloy, aluminum plate, aluminum sheet, perforated aluminum sheet or panel, corrugated aluminum sheet or panel, perforated aluminum ceiling panel, wall panel, metal wall panel, aluminum wall panel, wall cladding panel, metal wall cladding panel, aluminum wall cladding panel, curtain wall panel, aluminum curtain wall cladding panel, building material, suspension ceiling, decoration material, construction material

We're producing 3 types of corrugated aluminum sheets or panels, first type is singe corrugated aluminum sheet with typical thickness 0.4mm to 3.0mm, the second type is 2-layer corrugated aluminum composite panel which is made from a 0.6mm to 2.0mm flat aluminum sheet and a 0.2mm, 0.25mm, 0.3mm, 0.4mm or 0.5mm corrgated aluminum sheet (corrugation height is 3mm to 20mm) by adhesive bonding, the typical total thickness of composite panels is 4mm to 22mm, it's very popular for hook-up suspension ceiling system, the third type is 3-layer corrugated aluminum panel which is made from 2 flat aluminum sheets (thickness from 0.5mm to 2.0mm) and a corrugated aluminum sheet (thickness from 0.2mm to 0.5mm and corrugation height from 3mm to 20mm or custom specifications) by adhesive bonding in sandwich way, this type of corrugated aluminum sandwich composite panels is usually used for wall cladding and decoration or partitions because of its features of great flatness, high impact strength, low weight and uniform color. All the corrugated aluminum sheets or panels are pre-coated by roller coating with PVDF or Polyester coating, it can also be made by spray coating if necessary. We can customize and fabricate the corrugated aluminum sheets or panels according to your designs, specifications and requirements.

![]()

Our Corrugated Aluminum Panels present a premium solution for various construction, architectural, and industrial applications. These panels are meticulously crafted with a focus on durability, safety, and environmental responsibility. The product is designed to exhibit a high degree of fire resistance, proudly classified under the Class A2 category, ensuring peace of mind for our customers concerning fire safety and compliance with stringent building codes.

One of the key advantages of these corrugated panels is their low weight. This attribute makes them easy to handle and install, reducing overall labor costs and structural load. Despite their lightness, these panels do not compromise on strength. High strength is a core characteristic of our product, attributed to the superior quality of aluminum used and the precise manufacturing processes that enhance their rigidity and longevity. Good flatness is another feature, ensuring that each panel presents a smooth and uniform appearance when applied to any surface.

The panels come in a variety of thicknesses ranging from 0.1mm to 2.0mm, catering to a broad spectrum of requirements and ensuring versatility across different projects. Whether you need lightweight panels for decorative purposes or thicker, more robust panels for structural applications, our product line accommodates your needs with precision.

To meet diverse customer preferences and design specifications, our Corrugated Aluminum Panels come with a roller coating color finish. This finish not only adds to the aesthetic appeal of the panels but also provides an additional layer of protection against environmental elements. The roller coating process ensures a consistent and high-quality finish that enhances the product's durability and maintains its appearance over time.

The temper of the aluminum used in our panels ranges from O-H112. This indicates that our panels are available in various states of hardness and strength, from annealed (O) to full hard (H112), providing options that accommodate different levels of malleability and formability required by our clients’ specific applications.

We take pride in our commitment to environmental sustainability. Our Corrugated Aluminum Panels are not only environmentally friendly due to their recyclability, but they also contribute to greener building practices. The aluminum's recyclable nature means that it can be repurposed at the end of its life cycle, reducing waste and conserving resources. This feature is particularly important for organizations looking to meet eco-friendly standards and for individuals who prioritize environmental consciousness in their building materials.

In terms of specifications, our corrugated aluminum panels are available in a single aluminum thickness range from 0.15mm to 3.0mm, broadening the scope of applications and providing a tailored solution for specific structural requirements. The roller coating color finish, applied with precision and care, ensures that our panels are not only robust but also visually appealing, with a range of colors to match any design palette.

In summary, our Corrugated Aluminum Panels embody the perfect blend of functionality, safety, and eco-friendliness. With attributes like fire resistance (Class A2), low weight, high strength, good flatness, and a roller coating color finish, these panels are ideal for a multitude of projects that demand quality and durability. The range of thicknesses, from 0.1-2.0mm, and the option for single aluminum thicknesses from 0.15mm to 3.0mm, coupled with the varying temper states, make our product adaptable to your unique needs. Choose our Corrugated Aluminum Panels for a sustainable, strong, and visually compelling addition to your next project.

The RENOXBELL Corrugated Aluminum Panels, model CA-001, are a versatile and innovative solution for a wide range of architectural and design applications. These panels, originating from China and boasting an ISO9001 certification, are renowned for their quality and durability. They are available with a minimum order quantity of 500 square meters and are priced competitively between USD25-50 per square meter.

RENOXBELL's Corrugated Aluminum Panels come in various grades ranging from 1000 to 7000, with alloy codes including A1100, A3003, A5052, among others, catering to diverse project requirements. The panels are of the flat panel type, and one of the key attributes is that the corrugations can be customized to requests, ensuring that each project can have a unique aesthetic or functional feature.

Color customization is another significant advantage of these aluminum panels. Clients can choose the color to match their specific design palette, ensuring that the color can be customized to complement existing structures or to create new, visually striking environments. This feature is particularly beneficial for corporate branding or when adhering to local building codes and design guidelines.

When it comes to environmental responsibility, RENOXBELL has ensured that their Corrugated Aluminum Panels are recyclable, reflecting a commitment to sustainability and eco-friendly construction practices. This aspect is increasingly important in today's construction industry, where environmental impact is a critical consideration.

The ease and speed of installation are also key benefits. The panels are designed for quick assembly, reducing labor costs and speeding up the construction process, which is a crucial factor in meeting project deadlines and budget constraints. The panels come carefully packaged in plastic masking film and bubble sheets to ensure they arrive on-site in pristine condition.

RENOXBELL's supply ability stands at an impressive 20,000 square meters monthly, ensuring that even the most extensive projects can be supplied without delay. With a delivery time of 20-30 days and flexible payment terms, including T/T and L/C, RENOXBELL accommodates various client needs and project timelines.

In summary, the RENOXBELL Corrugated Aluminum Panels are an excellent choice for a myriad of applications, from commercial facades to decorative interior features. The combination of customized corrugations, color options, environmental friendliness, and easy installation makes these panels a go-to product for architects and builders seeking quality, customizability, and sustainability.

Brand Name: RENOXBELL

Model Number: CA-001

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 500 ㎡

Price: USD25-50 per square meter

Packaging Details: plastic masking film and bubble sheets

Delivery Time: 20-30 days

Payment Terms: T/T, L/C

Supply Ability: 20,000 square meters monthly

Processing Service: Welding, Punching, Cutting, Bending

Durability: Long-lasting

Temper: O-H112

Grade: 1000-7000 series

Alloy code: A1100, A3003, A5052 Etc.

Our Corrugated Aluminum Panels feature a roller coating color finish, ensuring a vibrant and durable surface. For installation convenience, they can also be made with angle taps for fixing. With their light weight and good flatness, these panels offer easy handling and installation. Additionally, they boast high impact strength for increased longevity.

Our Corrugated Aluminum Panels come with comprehensive technical support and services to ensure your complete satisfaction with our product. Our dedicated team of experts is available to provide guidance on installation, maintenance, and best practices to maximize the lifespan and performance of your panels. We offer detailed product documentation, including technical specifications, installation manuals, and care instructions, to support your needs. Additionally, we provide troubleshooting assistance and advice for common issues that may arise during the use of our panels. Our support services are designed to provide you with the confidence and knowledge you need to effectively utilize our Corrugated Aluminum Panels for your projects.

Q: What is the brand name of the Corrugated Aluminum Panels?

A: The brand name of the Corrugated Aluminum Panels is RENOXBELL.

Q: Can you provide the model number for the Corrugated Aluminum Panels?

A: Yes, the model number for our Corrugated Aluminum Panels is CA-001.

Q: Where are the RENOXBELL Corrugated Aluminum Panels manufactured?

A: The RENOXBELL Corrugated Aluminum Panels are manufactured in China.

Q: What certifications do the RENOXBELL Corrugated Aluminum Panels have?

A: Our Corrugated Aluminum Panels are certified with ISO9001.

Q: What is the minimum order quantity for the Corrugated Aluminum Panels?

A: The minimum order quantity for our Corrugated Aluminum Panels is 500 square meters.

Q: How much do the Corrugated Aluminum Panels cost per square meter?

A: The price for our Corrugated Aluminum Panels ranges from USD25 to USD50 per square meter.

Q: How are the Corrugated Aluminum Panels packaged?

A: The panels are packaged with plastic masking film and bubble sheets to ensure protection during transportation.

Q: What is the delivery time for an order of Corrugated Aluminum Panels?

A: The delivery time for our Corrugated Aluminum Panels is typically between 20-30 days.

Q: What are the terms of payment accepted for purchasing Corrugated Aluminum Panels?

A: We accept payment through T/T (Telegraphic Transfer) and L/C (Letter of Credit).

Q: What is the supply ability of RENOXBELL for Corrugated Aluminum Panels?

A: RENOXBELL can supply up to 20,000 square meters of Corrugated Aluminum Panels monthly.